Wilwood

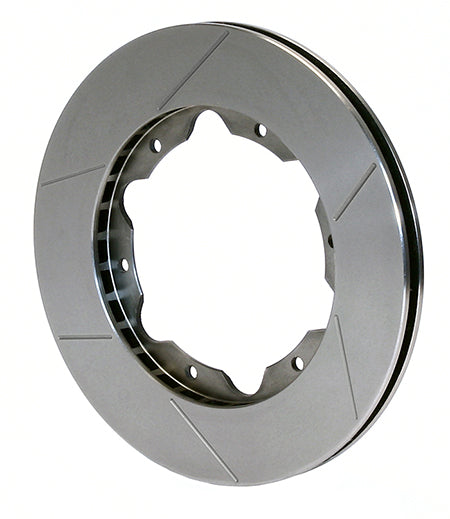

11" Wilwood 2-Piece Rotors for Powerlite Brake Kits — Plain, Slotted, or Drilled+Slotted Options

11" Wilwood 2-Piece Rotors for Powerlite Brake Kits — Plain, Slotted, or Drilled+Slotted Options

Couldn't load pickup availability

Big brake performance, lightweight construction, and fully serviceable—these are the real deal.

If you're building one of our Powerlite caliper-based Big Brake kits and want to get the most out of it, these 11" Wilwood rotors are the perfect match. Each rotor is a 2-piece design, meaning they’re made from a lightweight aluminum hat (also called a “bell”) and a high-quality steel disc bolted together with high-temp rotor hardware. This gives you better cooling, reduced unsprung weight, and the ability to replace just the ring when it wears out—without tossing the whole assembly.

Whether you're looking for plain-faced rotors for pure function, slotted for improved gas venting, or flashy SRP drilled+slotted discs for show and go—we’ve got all three options.

🔧 Rotor Breakdown:

Hat + Disc + Hardware = Complete Rotor = Package

Each kit includes everything you need to assemble your own 11" two-piece Wilwood rotor:

Hat Specs

-

Wilwood PN: 170-11682

-

Bolt Pattern: 4x100 (perfect for Miata and other 4-lug setups)

-

Offset: 0.750"

-

Rotor Bolt Circle: 6 x 6.25

Rotor Options (All 11" x 0.81")

-

Plain Face – Wilwood PN: 160-5840

Clean, simple, and track-proven. No nonsense. -

Slotted – Wilwood PN: 160-10358

Helps wipe the pad surface and vent gas under heat. -

SRP Drilled + Slotted – Wilwood PN: 160-7099-BK (Right) / 160-7100-BK (Left)

Flashy, functional, and symmetrical. Good for light track use or high-end builds.

Rotor Hardware Kit

-

Wilwood PN: 230-12176

-

Includes: 12 screws (6 per rotor)

-

Size: 5/16-18 x 1.00"

-

Material: CRES 321 stainless steel

-

Designed to handle serious brake heat

🛠️ Assembly Notes (Read This):

-

Use Loctite Red (high-temp threadlocker) on all hardware

-

Mount rotor to hat with the disc mass oriented outward

-

Tighten screws in a star pattern to 25 ft-lbs

-

Skipping Loctite or under-torquing can cause hardware failure. Don’t risk it—do it right.

Share